What Is The Characteristics And Operation Of Forged Steel Y-Type Strainer

Understand the characteristics and operation mode of the forged steel Y-typeStrainer. The pipe with the forged steel Y-type Strainer can be divided into intermittent operation and continuous operation during operation. In the case of intermittent operation, a shut-off valve is provided before and after the forged steel Strainer to clean the filter. For continuous operation, two sets of filters in parallel are required for the permanent filter, and the shut-off valves are respectively arranged before and after the filter.

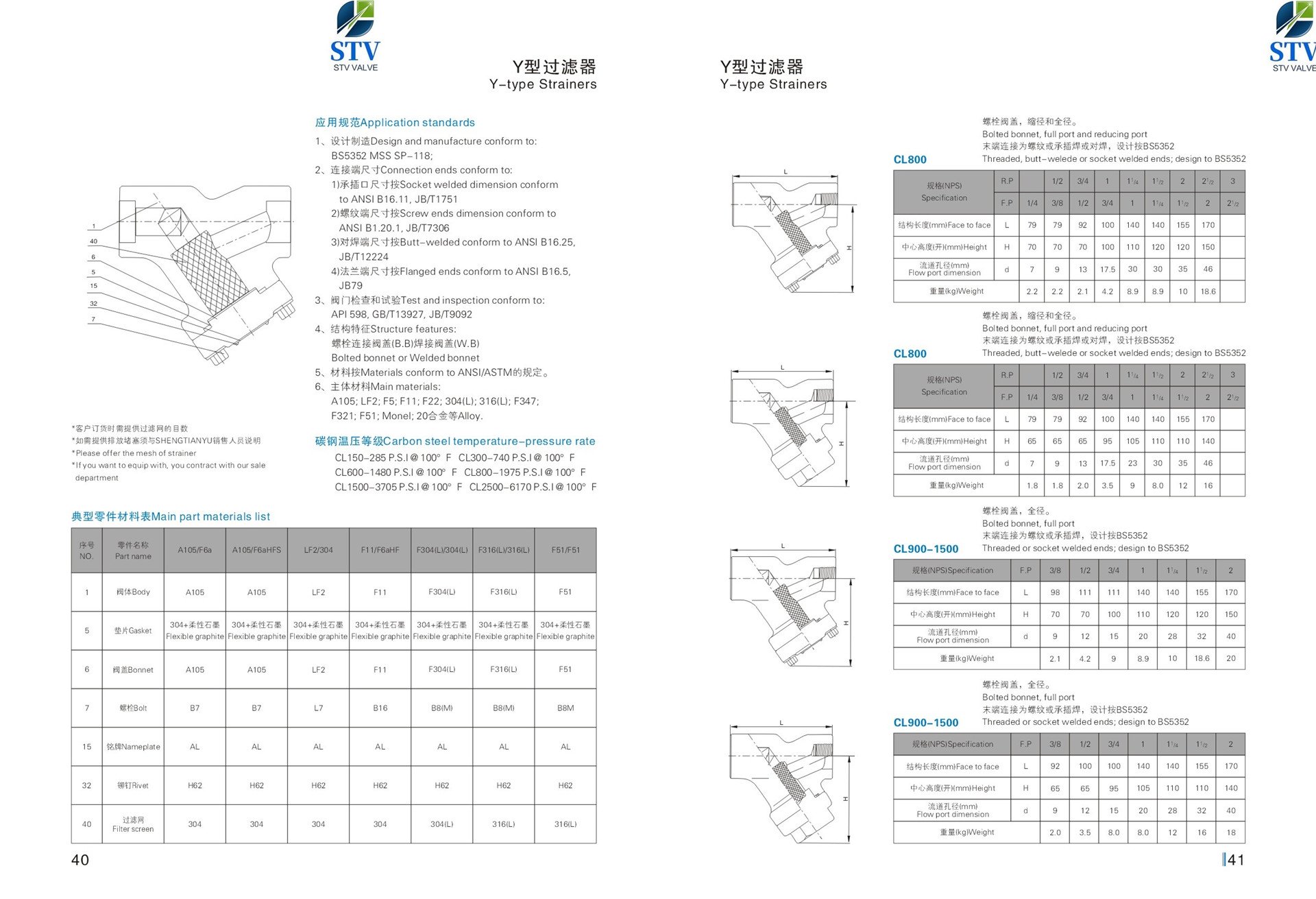

Characteristics of forged steel Y-type Strainer:

1, full diameter or reduced diameter.

2. The socket end is in accordance with ASME B16.11.

3, bolted, wound gasket sealed bonnet.

4. The threaded end (NPT) conforms to ANSI/ASME B1.20.1.

5, can be equipped with discharge blockage, replaceable filter.

STV Valve Technology Group Co., Ltd is China Class 800 Forged Steel Y-Strainer, FORGED STEEL Y STRAINER, Y Type Strainers and Filters , Y-Type Forged Steel (F22) Strainers,Y-Type Strainers,Forged steel Y-Strainer,Y-pattern strainer made of forged steel A105, manufacturer with high quality and low price.To learn more about this valve Welcome to contact Us.