1. Introduction to Bellow Seal Gate Valves

Bellow Seal Gate Valves are a crucial component in many industrial applications, providing a reliable and efficient way to control the flow of liquids or gases. Understanding the functionality of these valves is essential for anyone working in industries such as oil and gas, petrochemical, or power generation. In this ultimate guide, we will dive deep into the inner workings of a Bellow Seal Gate Valve, discussing its construction, operation, and benefits. Whether you are a China Bellow Seal Gate Valve Manufacturer, a supplier, or simply someone interested in learning more about this essential piece of equipment, this guide will provide you with the knowledge you need.

2. What is a Bellow Seal Gate Valve and how does it work?

A Bellow Seal Gate Valve is a type of valve that is specifically designed to provide a leak-free, low-maintenance solution for controlling the flow of fluids or gases. It is commonly used in industries where safety and reliability are paramount, such as oil and gas, petrochemical, and power generation.

The design of a Bellow Seal Gate Valve includes a bellows assembly, which is a flexible metal component that acts as a seal between the valve body and the stem. This bellows assembly allows the valve to operate smoothly and effectively, preventing leakage and ensuring a tight shut-off.

When the valve is open, the fluid or gas flows freely through the valve body and out of the outlet. To close the valve, the stem is rotated, causing the gate to move downward and block the flow. The bellows assembly ensures no leakage occurs during this process.

Overall, the functionality of a Bellow Seal Gate Valve is based on its ability to provide a reliable seal, control the flow, and prevent leakage, making it an essential component in various industrial applications.

3. Advantages of using Bellow Seal Gate Valves in industrial applications

Bellow Seal Gate Valves offer several key advantages that make them highly beneficial in industrial applications. Here are some of the advantages of using these valves:

1. Leak-Free Operation: The bellows assembly in Bellow Seal Gate Valves ensures a tight seal, preventing any leakage even in high-pressure applications. This feature significantly reduces the risk of hazardous leaks, making these valves ideal for industries where safety is a top priority.

2. Low Maintenance: The bellows assembly also acts as a barrier against corrosion and contamination, extending the lifespan of the valve and minimizing the need for frequent maintenance. This is particularly beneficial in industries where downtime is costly and productivity is a critical factor.

3. Smooth Operation: Bellow Seal Gate Valves are designed to operate smoothly with minimal friction, allowing for precise control of flow. This ensures efficient performance and reduces the chances of valve failure or damage.

4. High Reliability: With their robust construction and excellent sealing capabilities, Bellow Seal Gate Valves offer high reliability even in extreme operating conditions. These valves can withstand high temperatures, pressures, and abrasive fluids, making them suitable for demanding industrial environments.

In conclusion, the advantages of Bellow Seal Gate Valves make them a preferred choice in various industrial applications. Their leak-free operation, low maintenance requirements, smooth operation, and high reliability make them an essential component for industries where safety, efficiency, and productivity are crucial.

4. Understanding the different types of Bellow Seal Gate Valves

Bellow Seal Gate Valves come in various types, each designed to suit specific application requirements. Understanding these different types can help you select the most suitable valve for your industrial needs.

1. Rising Stem: This type of Bellow Seal Gate Valve is characterized by a stem that moves upward as the valve is opened, providing a visual indication of the valve’s position.

2. Non-Rising Stem: In this type, the stem does not move upward or downward as the valve is opened or closed. Instead, it rotates within the valve body, making it ideal for situations where space is limited.

3. Bolted Bonnet: These valves feature a bolted bonnet that allows for easy maintenance and repair. The bonnet is secured to the valve body using bolts, making it simple to remove and access the internal components.

4. Pressure Seal: As the name suggests, pressure seal Bellow Seal Gate Valves are designed to withstand high-pressure applications. They offer a superior seal against high-pressure conditions, preventing any leakage.

By understanding the different types of Bellow Seal Gate Valves, you can choose the one that best suits your specific industrial requirements. This knowledge will help you enhance the performance and efficiency of your operations.

5. Key components and materials used in Bellow Seal Gate Valves

Key components and materials used in Bellow Seal Gate Valves

Apart from the various types of Bellow Seal Gate Valves, it is important to understand the key components and materials used in their construction. This knowledge will help you make informed decisions when selecting the right valve for your specific industrial needs.

The main components of a Bellow Seal Gate Valve include the body, bonnet, stem, disc, and bellows. The body and bonnet form the outer casing of the valve, while the stem allows for the opening and closing of the valve. The disc acts as the gate, controlling the flow of the medium, and the bellows provide a flexible seal.

When it comes to materials, Bellow Seal Gate Valves are typically constructed using stainless steel, carbon steel, or cast iron. Stainless steel is a popular choice due to its corrosion resistance and durability. Carbon steel offers good strength and toughness, while cast iron is suitable for lower pressure applications.

Understanding the key components and materials used in Bellow Seal Gate Valves will enable you to select a valve that meets your operational requirements and ensures long-term reliability.

6. How to properly maintain and troubleshoot Bellow Seal Gate Valves

Regular maintenance is essential for ensuring the optimal performance and longevity of Bellow Seal Gate Valves. By following a few simple maintenance practices, you can prevent potential issues and increase the overall efficiency of your valve system.

One important step in maintaining Bellow Seal Gate Valves is to regularly inspect the bellows for any signs of wear, such as cracks or leaks. If any damage is detected, immediate replacement is recommended to prevent any further complications. Additionally, it is crucial to keep the valve clean and free from debris, as this can affect its functionality.

To troubleshoot any issues with a Bellow Seal Gate Valve, it is important to thoroughly understand its operation. Start by checking for any visible signs of leakage, such as puddles or stains around the valve. If a leak is identified, it is likely due to a faulty seal or damaged bellows.

In some cases, the valve may not fully close or open. This could be a result of obstruction in the flow path or a faulty stem. Carefully inspect the stem and ensure it moves freely without any obstructions. If necessary, clean or replace the stem to restore proper functionality.

Regular maintenance and troubleshooting practices will ensure that your Bellow Seal Gate Valve operates at its full potential, minimizing downtime and enhancing productivity in your industrial processes.

7. Industry standards and certifications for Bellow Seal Gate Valves

When choosing a Bellow Seal Gate Valve for your industrial application, it is crucial to consider industry standards and certifications. These standards ensure that the valve meets certain criteria for performance, safety, and reliability.

One widely recognized standard for Bellow Seal Gate Valves is the American National Standards Institute (ANSI) standard. This standard establishes specifications for valve design, materials, and testing procedures to ensure compatibility and quality.

In addition to ANSI, other industry organizations such as the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME) also provide guidelines and standards for valve manufacturing and performance. These standards help manufacturers and users maintain consistency and adhere to best practices.

When evaluating Bellow Seal Gate Valves, look for certifications such as the ISO 9001 or the ASME BPVC (Boiler and Pressure Vessel Code). These certifications demonstrate that the manufacturer has undergone rigorous quality checks and adheres to international standards.

By selecting a Bellow Seal Gate Valve that meets industry standards and certifications, you can have confidence in its reliability and performance, ensuring smooth operation in your industrial processes.

8. Conclusion: Harnessing the power of Bellow Seal Gate Valves in various industries

In conclusion, Bellow Seal Gate Valves play a vital role in maintaining the functionality and efficiency of industrial processes across various industries. By understanding the key features and considerations when selecting a valve, you can ensure smooth operation and optimal performance.

From their robust design to the use of bellows for improved sealing capabilities, Bellow Seal Gate Valves offer a reliable and cost-effective solution for controlling the flow of fluids and gases. Their ability to prevent leakage and withstand high-pressure and high-temperature conditions makes them particularly suitable for critical applications.

Furthermore, industry standards and certifications such as ANSI, ISO, and ASME provide valuable guidelines for manufacturers and users, ensuring that the valves meet specific performance criteria and adhere to best practices. These certifications also give users the confidence that the valves have undergone rigorous testing and quality checks.

In summary, Bellow Seal Gate Valves offer a wide range of benefits for industries in terms of safety, reliability, and performance. By understanding their functionality and selecting valves that meet industry standards, you can harness their potential and optimize your industrial processes.

.

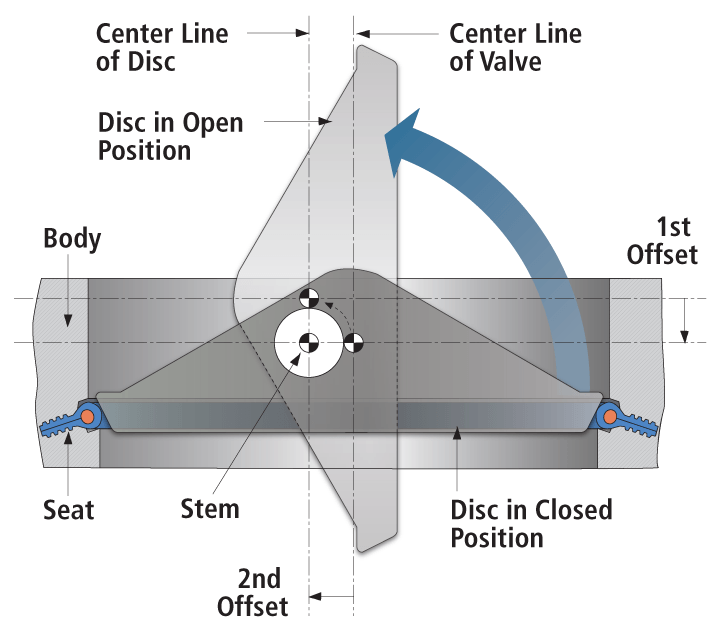

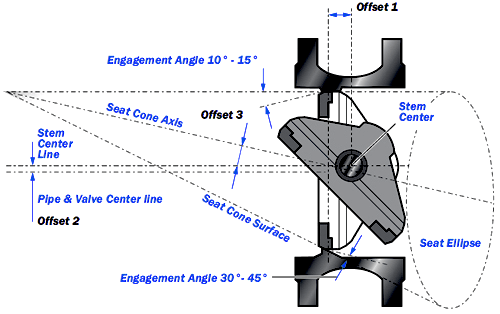

.  The images show the design difference between a double and a triple eccentric butterfly valve (respectively at the left and right side of the diagram).

The images show the design difference between a double and a triple eccentric butterfly valve (respectively at the left and right side of the diagram).