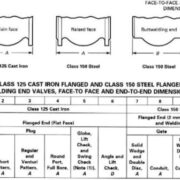

Face to Face Dimensions of Flanged Valves ASME B16.10

What is the face to face dimension of a flanged ball, globe or gate valve? The ASME B16.10 chart answers this question, as it standardizes the distance between the inlet and the outlet of the most common flanged valves. The purpose of this ASME specification is to ensure the interchangeability of valves produced by different manufacturers.

Notes:

- (1) Globe and horizontal lift check only.

The face-to-face and end-to-end dimension for Class 150 steel flanged swing check valves in NPS 5 is 330 and in NPS 6 is 356. - (2) Globe and horizontal lift check only.

The face-to-face and end-to-end dimension for Class 150 steel flanged swing check valves in NPS 16 is 864. - (3) Swing check only.

General notes:

- Dimensions are in millimeters unless otherwise indicated.

- The face-to-face dimension for flanged Valves is the distance between the extreme ends which are the gasket contact surfaces.

- End-to-End dimensions apply to flanged Valves where the gasket contact surfaces are not located at the extreme ends of the Valve. The distance between the extreme ends is described as the end-to-end dimension and applies to flanged Valves like: Ring Joint, large or small female and large or small groove.